Published 2023-10-11

abstract views: 30 // FULL TEXT ARTICLE (PDF): 20

Keywords

- CPM-10V steel,

- powder metallurgy,

- cutting parameters,

- ANOVA

How to Cite

Copyright (c) 2023 Journal of Production Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

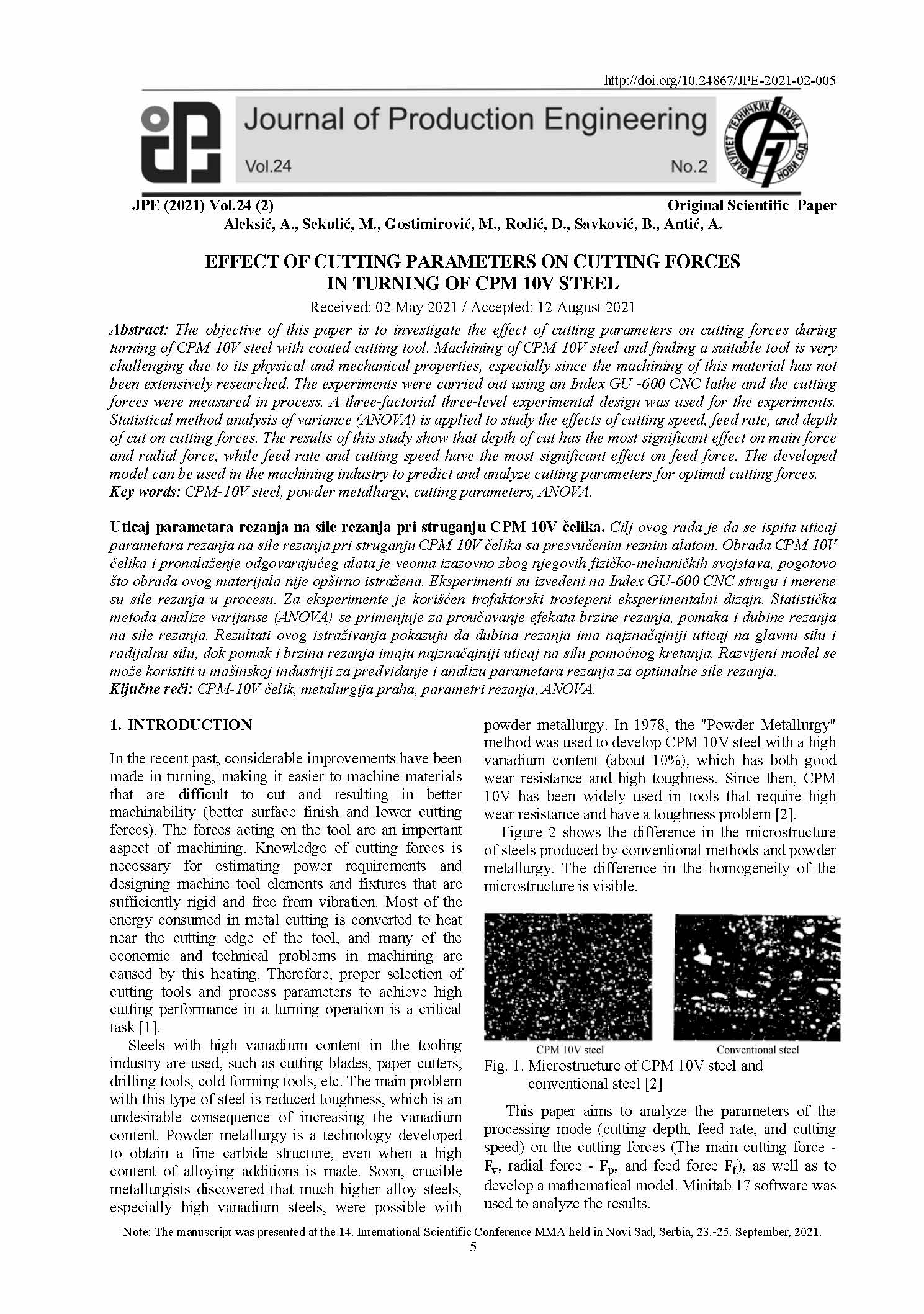

The objective of this paper is to investigate the effect of cutting parameters on cutting forces during turning of CPM 10V steel with coated cutting tool. Machining of CPM 10V steel and finding a suitable tool is very challenging due to its physical and mechanical properties, especially since the machining of this material has not been extensively researched. The experiments were carried out using an Index GU -600 CNC lathe and the cutting forces were measured in process. A three-factorial three-level experimental design was used for the experiments. Statistical method analysis of variance (ANOVA) is applied to study the effects of cutting speed, feed rate, and depth of cut on cutting forces. The results of this study show that depth of cut has the most significant effect on main force and radial force, while feed rate and cutting speed have the most significant effect on feed force. The developed model can be used in the machining industry to predict and analyze cutting parameters for optimal cutting forces.