Influence of cutting parameters on the quality of the cut surfaces of steel swith a laser beam

Published 2023-09-30

abstract views: 21

Keywords

- Laser cutting,

- cut surface,

- roughness measurement

How to Cite

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

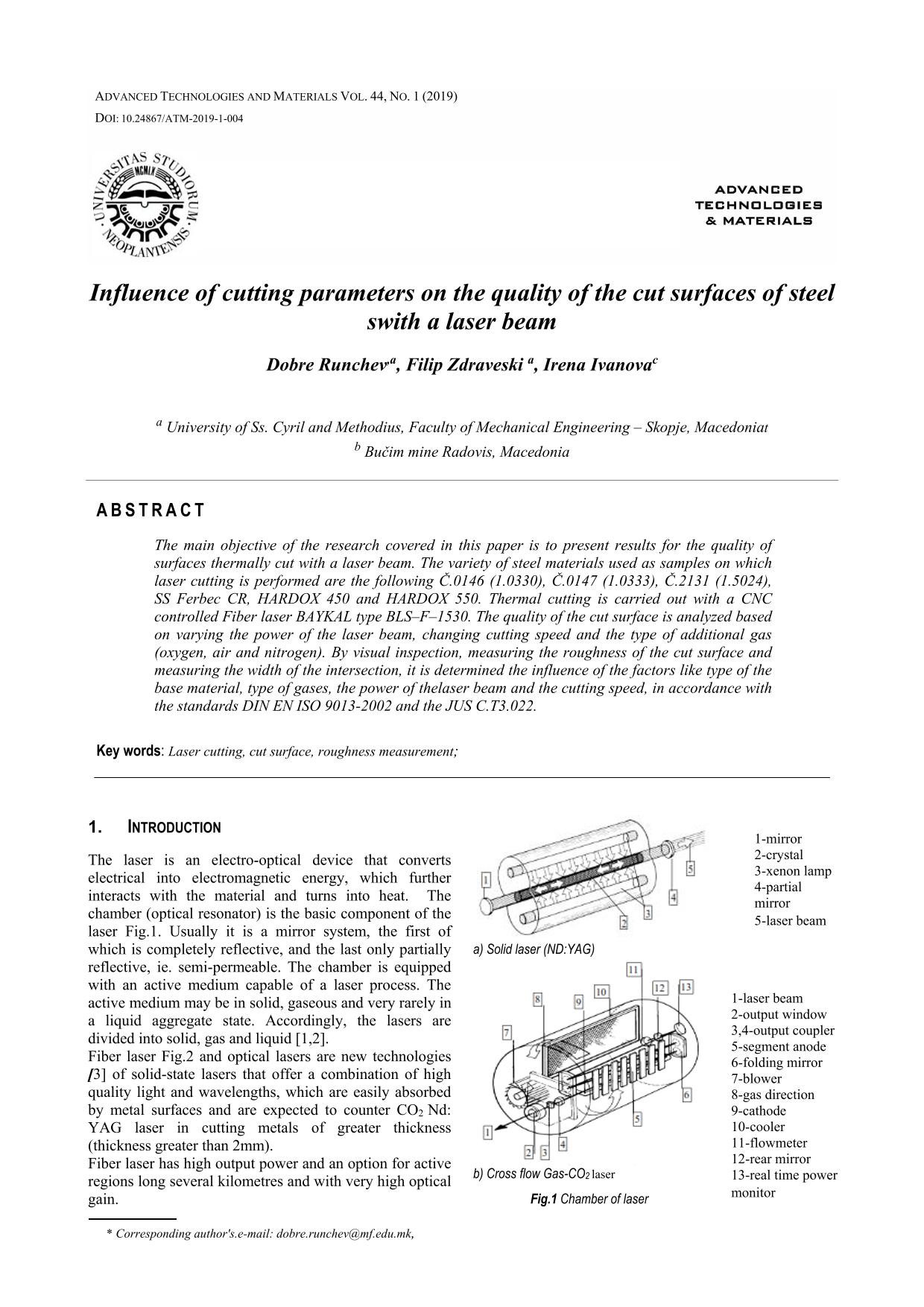

The main objective of the research covered in this paper is to present results for the quality of surfaces thermally cut with a laser beam. The variety of steel materials used as samples on which laser cutting is performed are the following Č.0146 (1.0330), Č.0147 (1.0333), Č.2131 (1.5024), SS Ferbec CR, HARDOX 450 and HARDOX 550. Thermal cutting is carried out with a CNC controlled Fiber laser BAYKAL type BLS–F–1530. The quality of the cut surface is analyzed based on varying the power of the laser beam, changing cutting speed and the type of additional gas (oxygen, air and nitrogen). By visual inspection, measuring the roughness of the cut surface and measuring the width of the intersection, it is determined the influence of the factors like type of the base material, type of gases, the power of thelaser beam and the cutting speed, in accordance with the standards DIN EN ISO 9013-2002 and the JUS C.T3.022.